Published: 2024-01-22 05:28:37

Published: 2024-01-22 05:28:37

Views: 1,118

Views: 1,118

admin

admin

Punching technology and its advantages and disadvantages

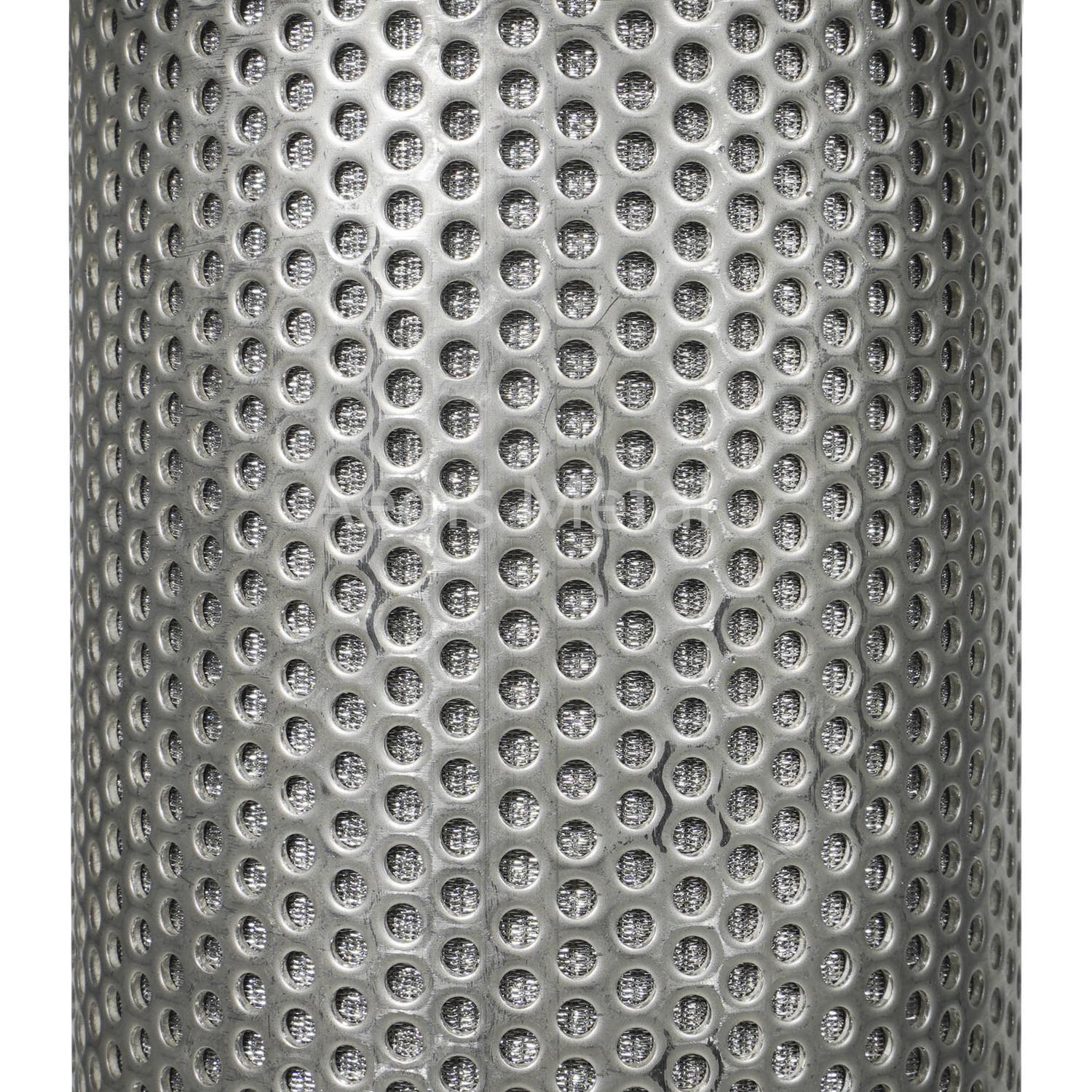

The process of stainless steel pipe punching mainly includes computer-aided design (CAD), program generation (CAM), screw drive and die secondary development and other processes. When the punch needle in the mold and the rectangular hole belt needle are inserted into the workpiece, the motor turns the punch needle to drill one or more holes in the workpiece. The rotor on the die then turns the workpiece to the next certain position, and the perforating needle again perforates precisely at different positions.

The advantages of punching technology are high processing efficiency, high accuracy, convenient mass production, etc., which can meet various needs for aperture and hole spacing. At the same time, the appearance of the punching technology is quite beautiful, no further processing is required, and it can play a role in rust prevention and corrosion prevention.

The main disadvantage of punching technology may be that the maintenance and maintenance cost of the machine is higher, and the design and selection of the mold need to take into account more details and requirements, and it is difficult to meet the goals of various needs.

Application of stainless steel pipe punching

Stainless steel pipe punching technology has been widely used in construction, decoration, shipbuilding, automobile, metallurgy, chemical industry and other industries. Among them, the construction, decoration and automobile industries will be stainless steel pipe punching technology applied to steel structure, bathroom equipment, pipe dredging and other fields, can make the product shape design become rich, beautiful, while the production efficiency has been greatly improved.

In the Marine and metallurgical industry, stainless steel pipe punching technology is mainly used in the manufacture of hull structural parts, offshore drilling rig components, bridge piers and high-speed rail tracks and other equipment, which can effectively improve the quality and durability of products.

The application of punching technology is still expanding, and more new industries and fields will incorporate it into the production process in the future.

perforated sintered filter tube

Stainless steel perforated tube

My WhatsApp: +86 13313083930

My email address : ruby@aegismetals.net

For more product pictures and videos, please contact me via WhatsApp or email

Hot News

Hot News