Published: 2025-08-06 11:06:48

Published: 2025-08-06 11:06:48

Views: 732

Views: 732

admin

admin

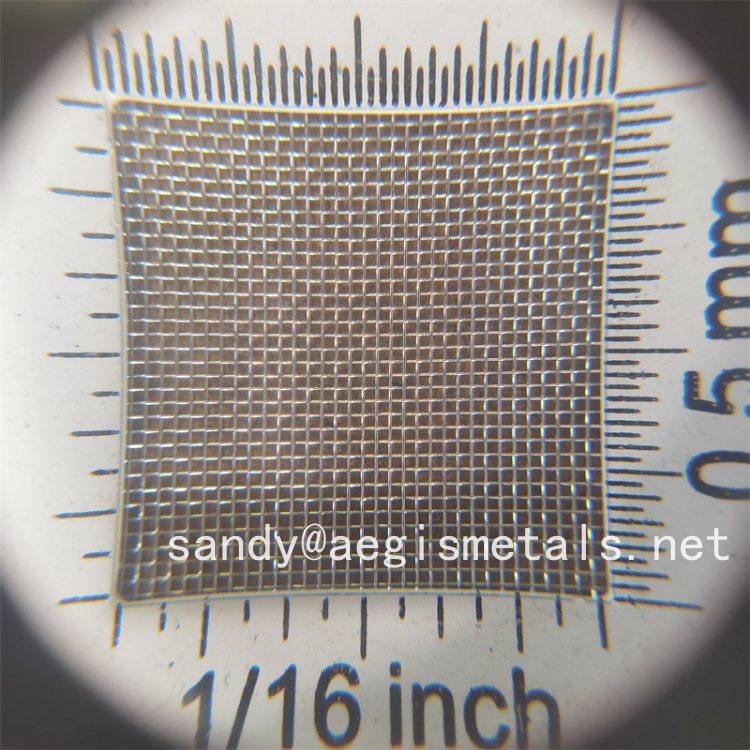

200×200 Mesh Count 0.05mm wire thickness nickel 200 mesh is a precision metal mesh woven from nickel or nickel alloy wire, with a mesh density of 200 holes per inch (approximately 78 holes/cm). It has characteristics such as high temperature resistance, corrosion resistance, high conductivity, and electromagnetic shielding, and is widely used in industrial filtration, electrode materials, and scientific research fields.

Structural parameters

-The aperture is about 90 μ m (micrometers), the rib width is 37 μ m, and the transmittance is about 50%

-Wire diameter range: 0.05mm (200 mesh standard) to 0.32mm (special specifications)

-Weaving methods: plain weave (basic filtration), twill weave (enhanced wear resistance), Dutch weave (ultra dense filtration). and 200×200 mesh size is in plain weave type !

Main application scenarios

(1) Industrial sector

Hydrogen production equipment: 120 mesh pure nickel mesh used as the core component of the electrolytic cell electrode

Chemical filtration: able to withstand high temperatures of 650-1100 ℃, used in petrochemical catalytic cracking units and flue gas treatment

Electromagnetic shielding: blocking electromagnetic radiation in shelters and medical equipment to protect human health

(2 )Research and Special Fields

Transmission Electron Microscopy (TEM): As a carrier for biological samples, it needs to be used in conjunction with Formvar film (10nm thick)

Fuel cell: 100-200 mesh nickel mesh is used as the electrode current collector, with strong conductivity

How to choose a suitable TEM carrier network

Selection of copper mesh for commonly used transmission electron microscopy (TEM)

Purchase precautions

Accuracy verification: There may be a deviation between the measured aperture and the nominal mesh size (such as a 15% accuracy fluctuation caused by a material thickness of ± 0.1mm)

Special requirement: When analyzing copper elements, nickel/molybdenum carrier mesh should be selected to avoid interference with the detection results

Production and Supply

Support customized tensile strength and hole opening accuracy

If specific model parameters (such as wire diameter mesh correspondence table) or application cases are required, further requirements details can be provided.

Our email is sandy@aegismetals.net +86-15003386113

Hot News

Hot News