Published: 2025-09-19 11:36:08

Published: 2025-09-19 11:36:08

Views: 247

Views: 247

admin

admin

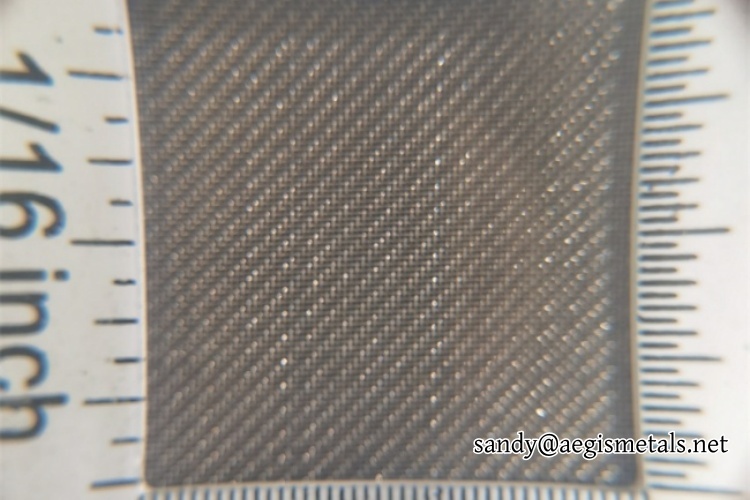

Stainless Steel Filter Wire Mesh In 350 363 400 500 550 600 625 635 Mesh

these very high mesh count woven filter mesh belong to the field of precision filtration, used for separating extremely fine particles. The twill weaving method is key to achieving these high mesh counts.

High Mesh Count: Ranging from 350 to 635 Mesh, meaning there are hundreds of openings per linear inch (25.4mm). The higher the mesh count, the smaller the aperture, and the higher the filtration precision.

Twill Weaving: For high mesh count sieves, plain weave is almost impossible. Twill weaving is characterized by each weft wire passing alternately over two and under two warp wires (2/2 weave). This structure provides:

Stainless Steel Material: Usually made from SUS 316L (most common, good corrosion resistance) or SUS 304. 316L is the preferred choice for filtration applications due to its excellent chemical corrosion resistance and pitting resistance.

|

Mesh Count |

Approx. Aperture (μm) | Approx. Wire Diameter (μm) | Characteristics & Application Areas |

|---|---|---|---|

| 350 | 40 – 30 | 35 – 40 | Starting point for fine filtration. Used for fine powder sieving, high-precision screen printing, battery slurry filtration, and coarse chemical liquid filtration. |

| 363 | ~35 | ~35 | Similar to 350 Mesh, a common specification under certain standards. Used for scenarios requiring more consistent filtration. |

| 400 | 30 – 25 | 30 – 35 | Standard fine filtration. Commonly used in precision industrial filtration, such as inks, coatings, ceramic powders, and high-end printing screens. |

| 500 | 25 – 20 | 25 – 30 | Ultra-fine filtration. Used for electroplating solution filtration, injectable solution pre-filtration, and grading of high-demand powders (e.g., metal 3D printing powders). |

| 550 | 22 – 18 | 23 – 28 | Higher filtration precision. Applied in specific industries with stringent filtration standards, such as special chemicals or precious metal catalyst recovery. |

| 600 | 20 – 15 | 20 – 25 | Extremely fine filtration. Used for aerospace fuel filtration, hydraulic oil filtration, photoresist filtration, and other extreme environments. |

| 625 | ~18 | ~22 | Sits between 600 and 635 Mesh, a specification designed to meet specific filtration precision requirements. |

| 635 | 15 – 10 | 15 – 20 | Ultra-high precision filtration. Nearing the limit of woven mesh. Used in laboratories, the semiconductor industry, nanomaterial pre-screening, and top-tier screen printing. Very fragile, prone to clogging. |

Hot News

Hot News