Published: 2025-06-10 02:37:28

Published: 2025-06-10 02:37:28

Views: 782

Views: 782

admin

admin

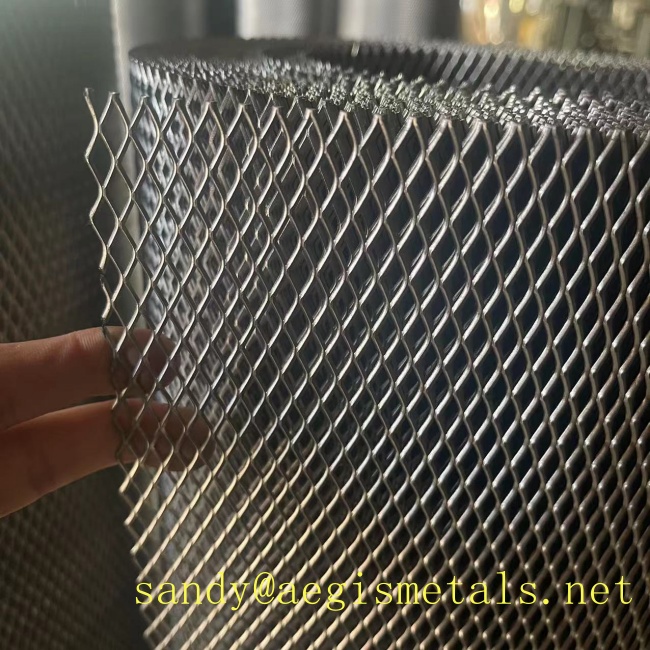

Nickel Expanded Metal is made by expanding pure nickel foil by precision expanding technique. The Mini nickel expanded metal fits best for battery and fuel cell electrodes and current collector, for example nickel-compartment/Ni-Hi/Li-ion battery electrode.

Nickel Expanded Metal is symmetrically slit and stretched to produce diamond shape openings. This type of nickel mesh has avoided the electricity flow problem that occurs in mesh made of woven wires.

We take the special measures to produce the nickel expanded metal mesh with smooth surface.

Common Nickel Expanded Metal Specification Range:

Opening size(LWD): 0.2mm to 20mm

Thickness: 0.1mm to 5mm

Sheet size: customized sizes available

Hot News

Hot News