| Material | 304/316/316L stainelss steel grade mesh |

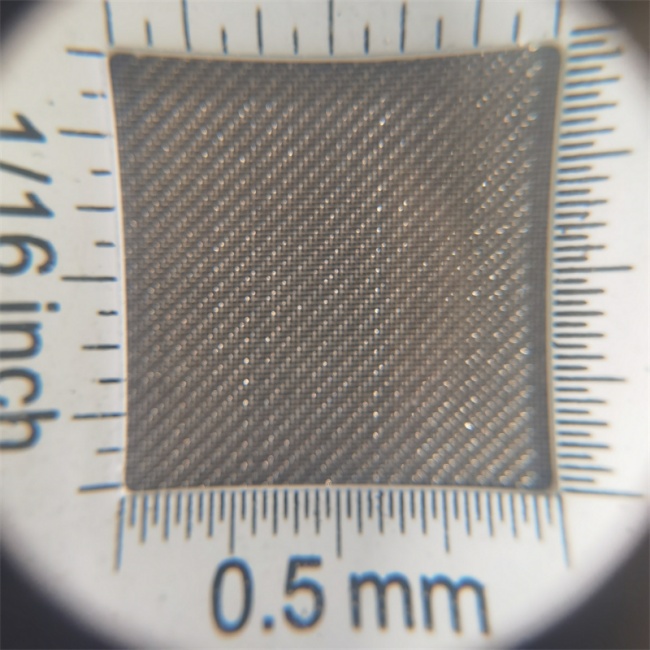

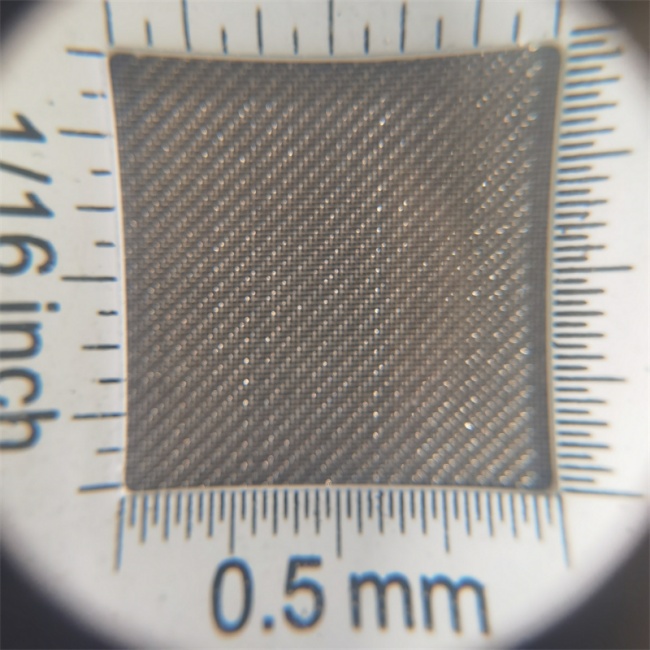

| Micron size | 1um 2um 3um 4um 5um 6um 7um 8um 10umn 15um 20um 25um…100 micron |

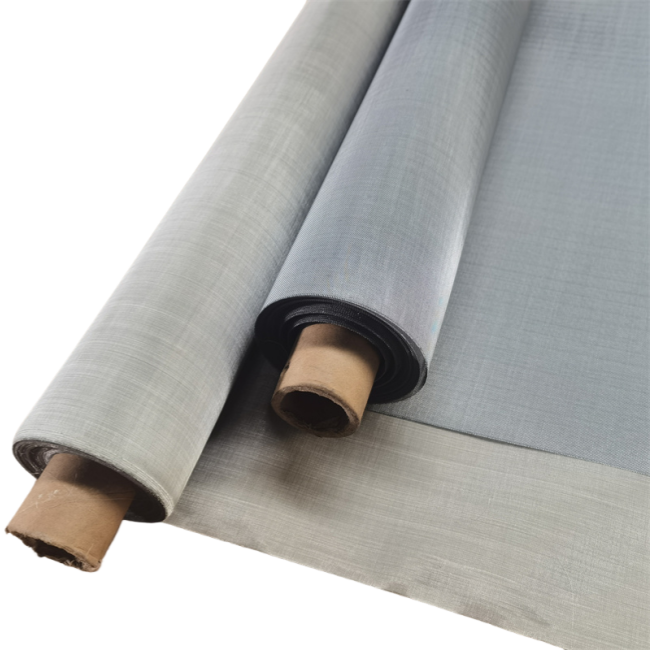

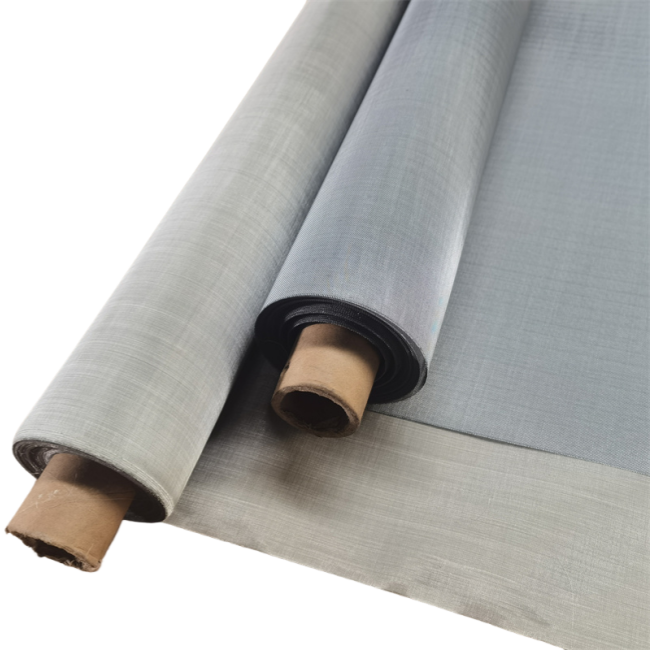

| Roll Size | 1mx30m/roll |

| Custom size | Can be made |

| Contact | sandy@aegismetals.net +86-13623380888 |

Products

In industrial production, laboratory research, and even daily life, precision filtration plays a critical role in ensuring product quality, operational safety, and environmental compliance. Among the various filtration materials available, 1 2 3 4 5 micron stainless steel filter mesh (also written as 1um 2um 3um 4um 5um 10um 25um pore size stainless steel wire mesh )stands out as a reliable and high-performance option, thanks to its unique combination of precision, durability, and corrosion resistance.

| Material | 304/316/316L stainelss steel grade mesh |

| Micron size | 1um 2um 3um 4um 5um 6um 7um 8um 10umn 15um 20um 25um…100 micron |

| Roll Size | 1mx30m/roll |

| Custom size | Can be made |

| Contact | sandy@aegismetals.net +86-13623380888 |

Main characteristics and advantages of micron stainless steel wire mesh

(1) High precision and consistency: It can produce various precise pore sizes ranging from 1 micron to several hundred microns, with very stable and reliable screening and filtering effects.

(2)Exceptional strength and durability: The stainless steel material endows the filter screen with exceptional mechanical strength, enabling it to withstand high pressure, high flow rates, and drastic temperature changes, making it less prone to damage.

(3)Excellent corrosion resistance: 304 and 316 stainless steels have good acid resistance, alkali resistance, and rust resistance, and can adapt to various complex chemical environments, with a long service life.

(4)High temperature resistance: It can operate in high temperature environments (such as several hundred degrees Celsius) for extended periods of time without melting or deforming, unlike plastic filters.

(5)Easy to clean and reusable: Due to its sturdy structure, it can be thoroughly cleaned through ultrasonic cleaning, backwashing, baking, etc. after being blocked, enabling multiple cycles of use and reducing long-term costs.

(6)Good processability: It can be further processed into various shapes, such as filter discs, filter cartridges, filter baskets, filters, etc.

Due to its excellent performance, micron-sized stainless steel filter wire mesh are used in numerous industries with stringent filtration requirements: