| Material | Nickel200. |

| Purity | Ni is over 99.95% |

| Thickness | 0.25mm 0.4mm 0.6mm 0.8mm 0.5mm commonly |

| Layer sheet size | from 100x100mm to 1000x1000mm |

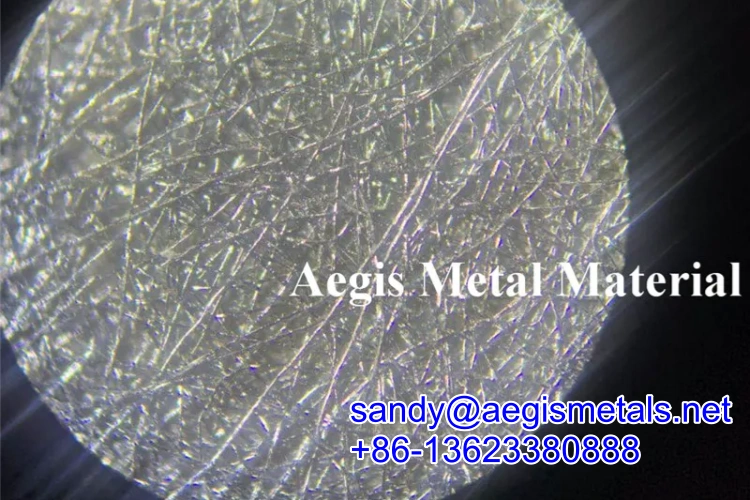

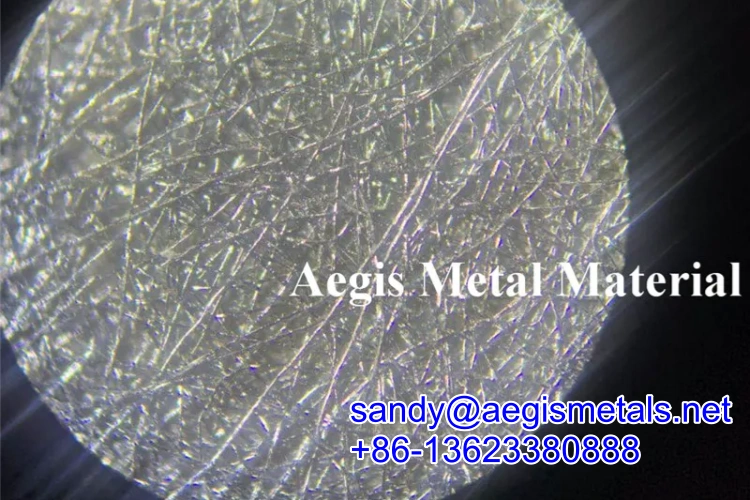

| Nickel Fibers wire | 25-40um ultra thin |

| Any other size, please contact us. | |

Products

Nickel felt is widely used as a gas liquid diffusion layer (GDL), particularly in alkaline electrochemical systems like alkaline fuel cells and water electrolyzers, due to its excellent properties. sintered type pure nickel felt serves as a highly effective, corrosion-resistant, and conductive GDL/electrode material in electrochemical applications where carbon is unsuitable, particularly in alkaline environments!

| Material | Nickel200. |

| Purity | Ni is over 99.95% |

| Thickness | 0.25mm 0.4mm 0.6mm 0.8mm 0.5mm commonly |

| Layer sheet size | from 100x100mm to 1000x1000mm |

| Nickel Fibers wire | 25-40um ultra thin |

| Any other size, please contact us. | |