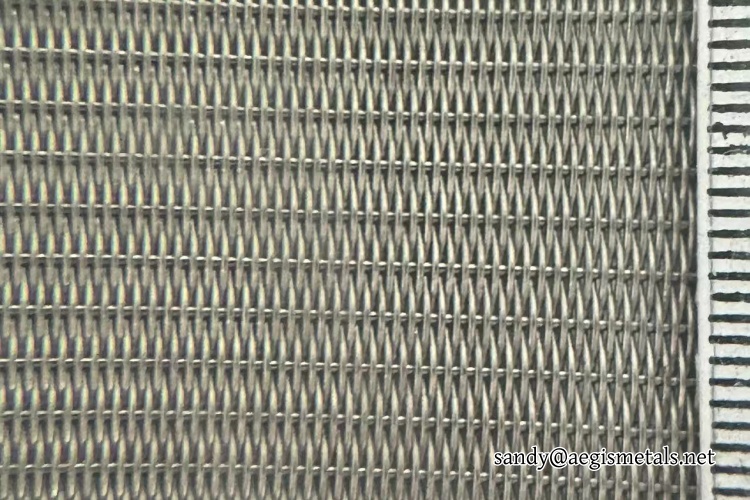

Plain Dutch Weave (Holland Weave) Type: The standard form, offering good strength and fine filtration.

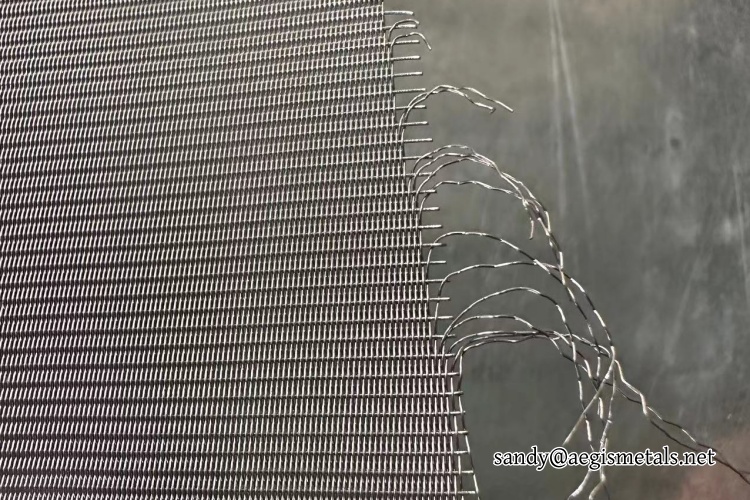

Twill Dutch Weave Type: The weft wires pass over and under two warp wires. This allows for even finer filtration and higher strength for a given mesh count, but at a higher cost.

| Weave Type | Warp x Weft (wires/inch) | Warp Wire (mm) | Weft Wire (mm) | Nominal Filtration Rating (µm) |

|---|---|---|---|---|

| Plain Dutch | 24 x 110 | 0.50 | 0.28 | 105 – 115 |

| Plain Dutch | 40 x 200 | 0.32 | 0.23 | 50 – 60 |

| Plain Dutch | 50 x 250 | 0.25 | 0.20 | 35 – 40 |

| Plain Dutch | 80 x 700 | 0.21 | 0.15 | 15 – 20 |

| Twill Dutch | 24 x 110 | 0.50 | 0.28 | 80 – 90 |

| Twill Dutch | 40 x 200 | 0.32 | 0.23 | 40 – 45 |

| Twill Dutch | 50 x 250 | 0.25 | 0.20 | 25 – 30 |

| Twill Dutch | 80 x 700 | 0.21 | 0.15 | 10 – 15 |

| Twill Dutch | 165 x 1400 | 0.14 | 0.10 | 5 – 10 |

| More mesh sizes needed, please contact us, sandy@aegismetals.net | ||||

Material: SUS 304 304L 201 316 316L 904L

Roll Width: 1m-2m

Roll length: 30M/roll 15m/roll