| Feature | Ni Felt | Traditional Materials (e.g., nickel mesh, ceramic foam) |

|---|---|---|

| Porosity & Surface Area | Higher (50%–85%), interconnected pores | Lower (30%–60%), less uniform pore distribution |

| Flexibility | Ductile, bendable | Rigid (ceramic) or brittle (thick mesh) |

| Conductivity | Excellent (metallic) | Good (mesh) but poor (ceramic) |

| High-Temp Resistance | Stable up to ~1,000°C | Ceramic: higher, but brittle; mesh: prone to deformation |

Ni fiber felts are now widely used in to the AEM water electrolysis.

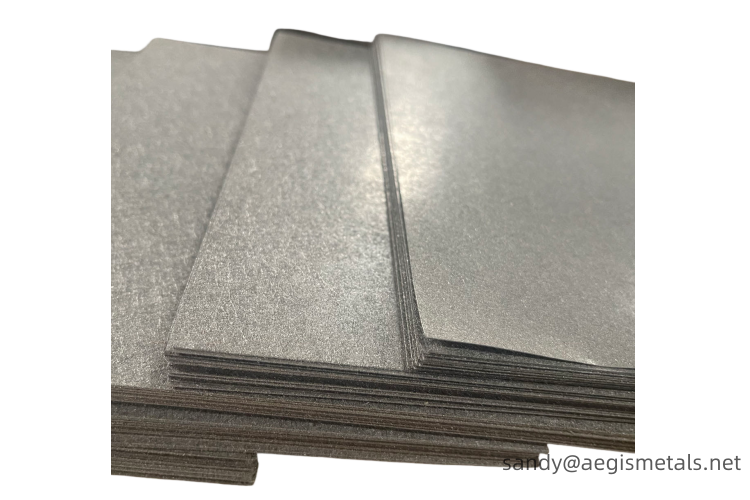

The Thickness from 0.2mm to 2.0mm, Porosity from 50-85%, Sheet size from 100x100mm to 1000x1000mm, Materials from Ni200 to Ni201, all can be custom made,

More info, please contact us sandy@aegismetals.net