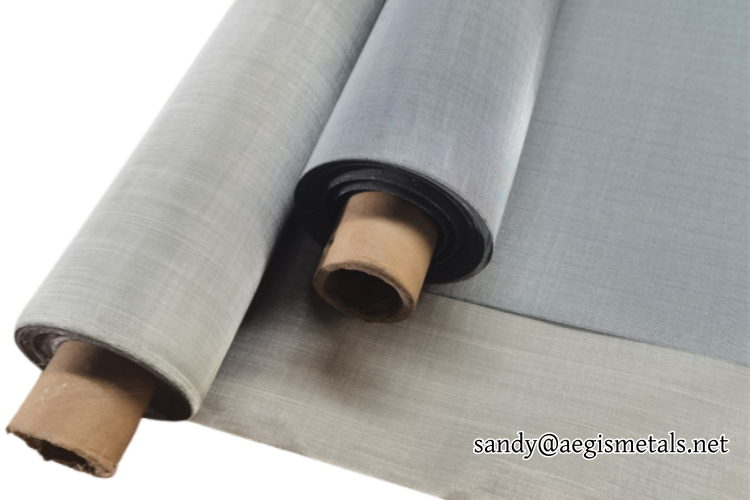

Key Specifications of 325 mesh stainless steel mesh gauze:

-

Mesh Count: 325 openings per linear inch.

-

Mesh Opening: The space between the wires is very small, typically around 44 microns (0.0017 inches or 44 μm). This is often used as a benchmark for fine particle filtration.

-

Wire Diameter: The individual wires used in this mesh are very thin, usually around 0.0014 inches (36 μm). A thinner wire allows for more open area.

-

Open Area: The percentage of the total area that is open space for flow. For 325 mesh, this is typically around 30%, which is relatively low due to the high number of fine wires.

-

Material: Almost always made from Stainless Steel 304 or 316.

-

SS 304 (AISI 304): The most common grade, offering excellent corrosion resistance for general purposes.

-

SS 316 (AISI 316): Superior corrosion resistance, especially against chlorides and acids. Preferred for marine, chemical, and high-purity applications.

-