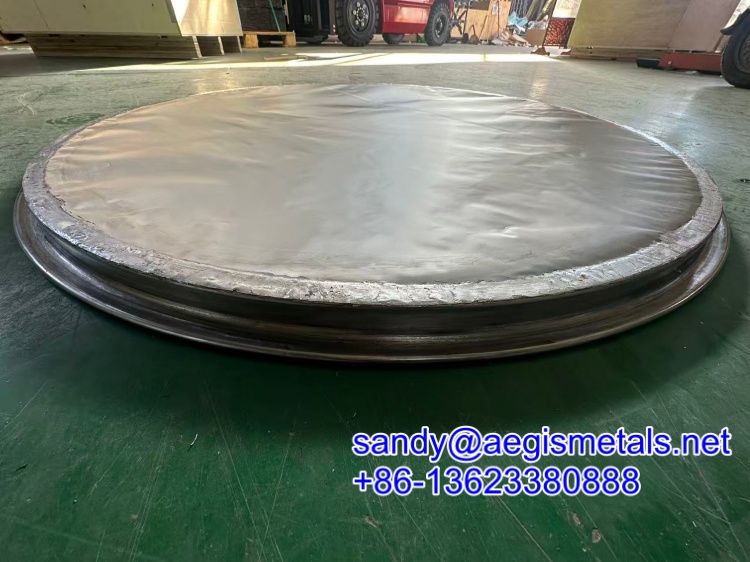

| Material for micron mesh |

304/316 Stainless steel micron mesh, and other metal materials. |

| Material for metal substrate | such as ss, and carbon steel |

| Filtering Accuracy | 10-500 mesh size for different impurity interception request. |

| Sizes for the filter disc | 50-5000mm |

| Welded width | 0.8mm -2mm, 2-50mm custom |

| Operating temperature | -20~150 ℃ |

| Pressure resistance | ≤ 5.6MPa |

|

We can accept any custom sizes orders, and can accept the processing service only if needed. More info, please contact sandy@aegismetals.net |

|