| Material | SUS304 316 316L grade stainless steel |

| Thickness | 0.05-0.6mm |

| Notes |

1、 Low cost of mold opening products, allowing for arbitrary mold modifications to reduce design and development costs More infomation needed, please contact us directly. |

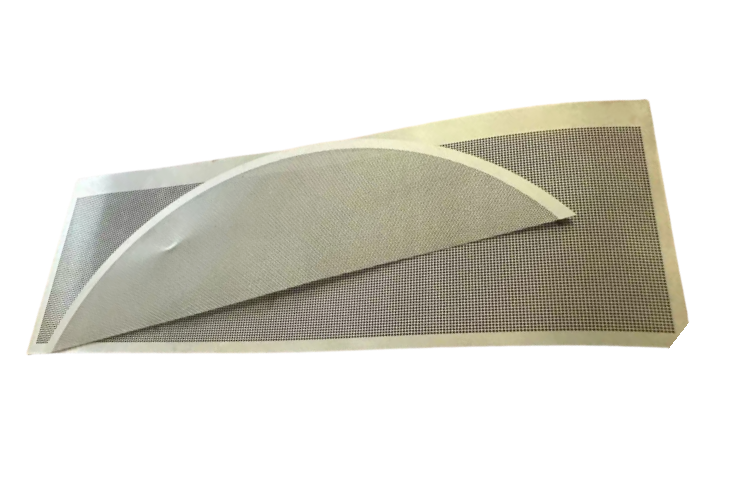

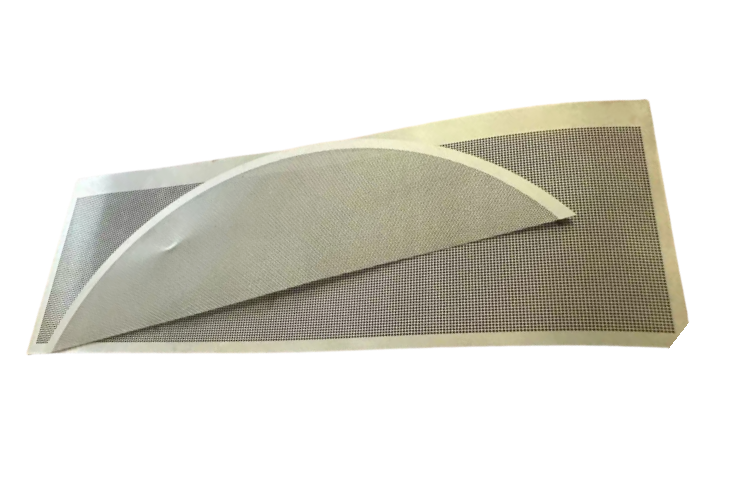

Metal Foil Sheet/Expanded Metal Mesh

Etching Metal Mesh, Etched sheet, is the use of chemical etching to selectively remove some material from the surface of metal sheets, thereby forming a mesh structure with specific patterns, holes, or shapes. The basic principle is to pretreat the surface of the metal sheet that needs to be etched (such as stainless steel, copper, aluminum, etc.), covering it with a layer of corrosion-resistant layer (such as by coating photosensitive ink, etc.), and then remove the corrosion-resistant layer in the area that needs to be etched through exposure, development, and other steps, exposing the metal. Next, place the metal plate into the etching solution, which will react chemically with the exposed metal, gradually dissolving the metal in these areas, while retaining the areas protected by the corrosion-resistant layer, ultimately forming the designed metal mesh structure.

| Material | SUS304 316 316L grade stainless steel |

| Thickness | 0.05-0.6mm |

| Notes |

1、 Low cost of mold opening products, allowing for arbitrary mold modifications to reduce design and development costs More infomation needed, please contact us directly. |

Etched mesh with High precision : Etching technology can achieve very fine pattern and hole processing, such as creating holes with diameters as small as tens of micrometers, and accurately controlling hole spacing, line width, etc. within a very small range. It is suitable for electronic components, precision instruments, and other fields that require high precision.

Etched metal mesh with Diversified patterns: Various complex patterns can be created according to design requirements, including geometric shapes, text, logos, and artistic patterns, providing great convenience for personalized design and decorative applications of products. They are commonly used in architectural decoration, artistic creation, and other fields.

Etched mesh sheet Strong material adaptability:Almost all metal materials that can undergo chemical reactions with etching solutions can be etched, covering common metals and alloys such as stainless steel, copper, aluminum, nickel, titanium, etc., which can meet the diverse needs of different industries for metal mesh materials.

Etched metal plate with Good mesh uniformity: Through precise process control, the mesh holes of the etched metal mesh can maintain good uniformity in size, shape, distribution, and other aspects, which is very important for some application scenarios that require uniform permeability, such as filtration, screening, ventilation, etc.

Electronics industry: Using etched metal mesh, utilizing its high precision, good conductivity, and electromagnetic shielding properties, to ensure the normal operation and electromagnetic compatibility of electronic devices.

Filtering and screening field: With its high-precision mesh and good uniformity, etched metal mesh can be used in various precision filtration applications.

Architectural decoration: Etching metal mesh can produce various exquisite patterns and textures through etching, which can be used for exterior decoration, interior partitions, ceiling decoration, etc. of buildings.

Automotive industry:Etched metal mesh can be used for components such as air intake grilles and heat dissipation grilles in cars. It not only ensures air circulation, but the etched patterns can also increase the aesthetic appearance of the car.

Aerospace field:Due to its high precision and reliable quality, etched metal mesh can be used for precision components in aerospace equipment.