(1) Material: Pure Nickel (Nickel200 Nickel201) or other nickel based alloy metal

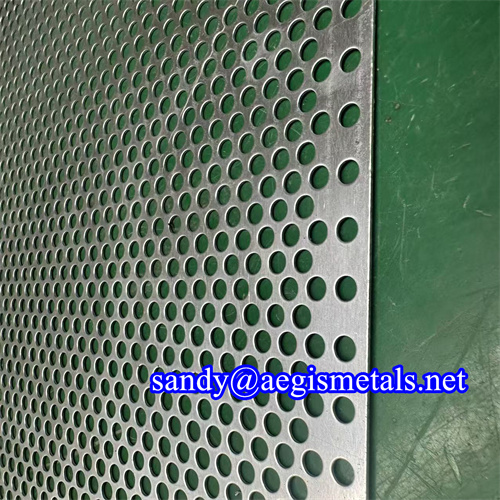

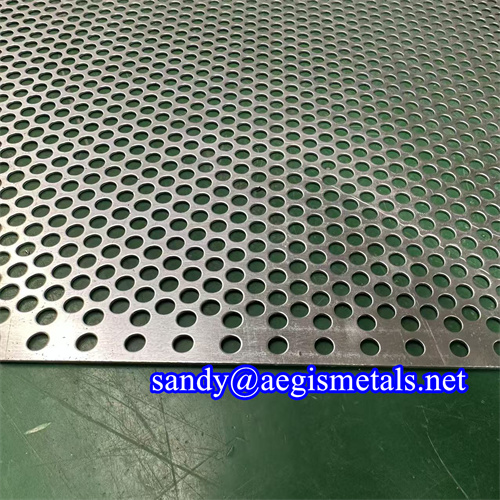

(2) Hole shapes:

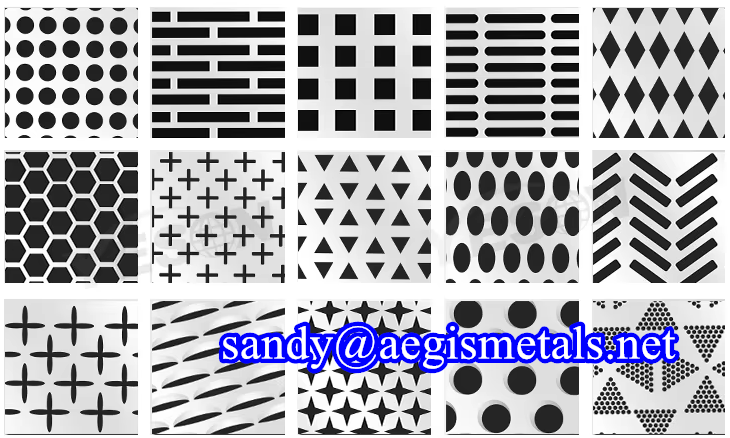

–Round Holes: Most common (straight, staggered).

–Square Holes.

–Slot Holes (Round-ended or Straight): Good for directional flow or screening.

–Custom Patterns: Hexagonal, decorative designs, etc.

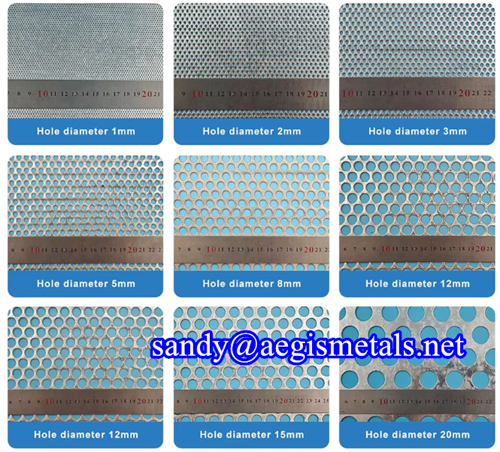

(3) Hole Size (Diameter/Width): Ranges from fractions of a millimeter (mm) to several centimeters, usual 0.1–200mm.

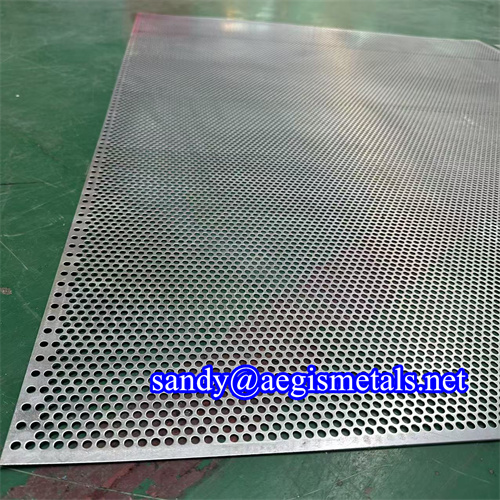

(4) Stagger (Pitch): Distance between hole centers (on-center, OC).

(5)Open Area (%): The percentage of the total sheet area occupied by holes. Crucial for flow, filtration, and visibility.

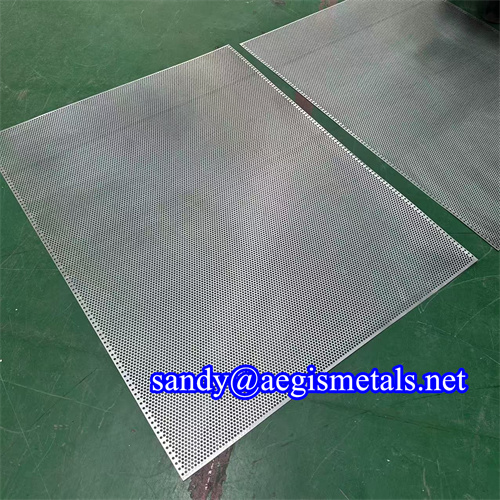

(6)Sheet size: 1x1m 1x2m 0.5x1m 1.2×2.4m or request cutting size.

(7) Sheet thickness; 0.05mm to 20mm

(8) Hole arrangement: 90°staggered,45°staggered, 60°staggered , 90°straight

More info, please contact us directly via sandy@aegismetals.net