How the Ti felts manufactured?

(1) Titanium Fiber Preparation: titanium raw materials are processed into micron-sized titanium fibers, which can be obtained through methods such as mechanical drawing, chemical vapor deposition, and electrospinning.

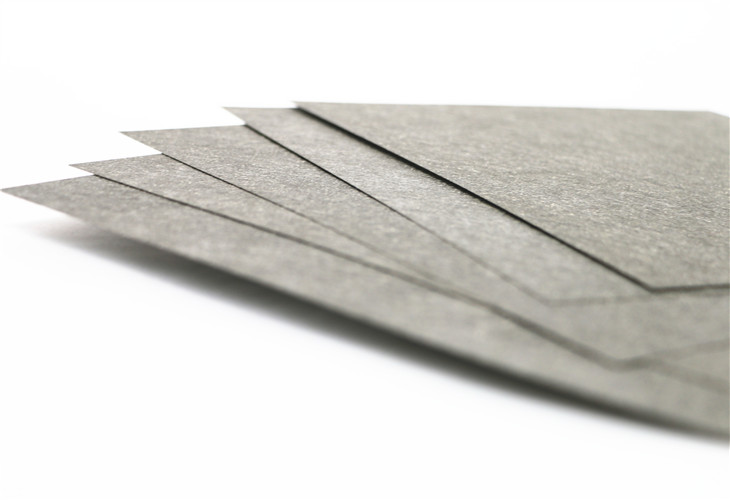

(2) Lay-up the Ti fibers: Titanium fibers are laid up in a certain way to form a fiber felt blank with a certain thickness and shape. The lay-up method will affect the pore structure and performance of the titanium felt.

(3)Sintering the ti fibers together: The fiber felt blank is sintered in a high-temperature vacuum environment. At high temperatures, the nodes between titanium fibers will fuse to form a solid three-dimensional network structure, which improves the strength and stability of the titanium felt.