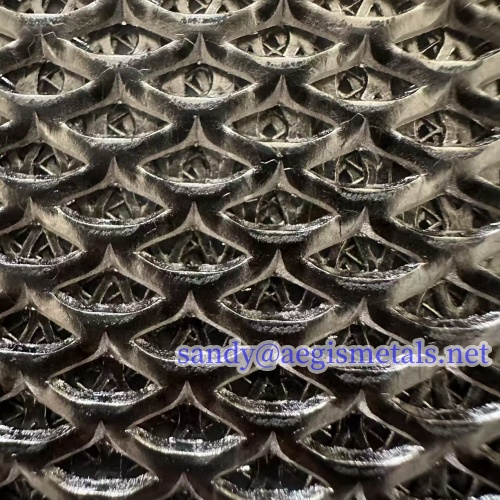

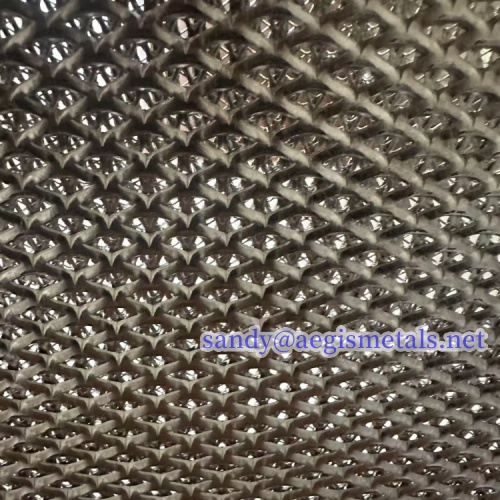

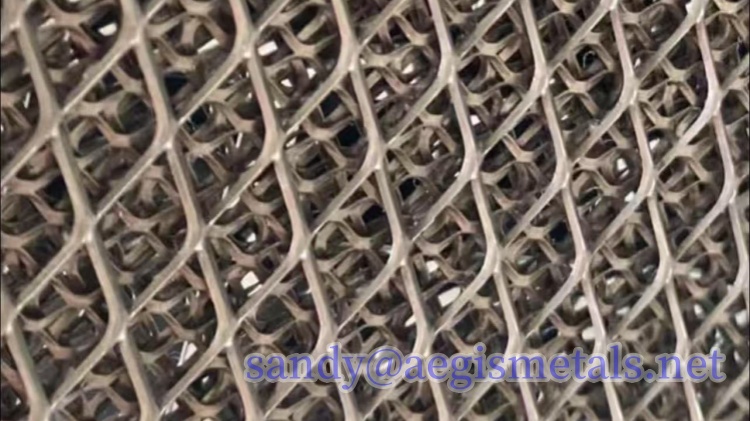

-Material:99.95% pure nickel, Ni200 Ni201, N2, N4, N6…

-Production Process: Expanded, Sintering, Cutting

-Layers: 2 layer, 3 layer, 4 layers, or customized

-Thickness: 1.4mm 1.0mm 2.0mm 2.3mm

-Poroisty: No less than 65%.

-Sheet Width: from 50mm to 1000mm

-Sheet Length: from 500mm to 1500mm

-Each layer sizes, please contact sandy@aegismetals.net

-Custom size; any sizes can be produced according to the customer’s requirement.